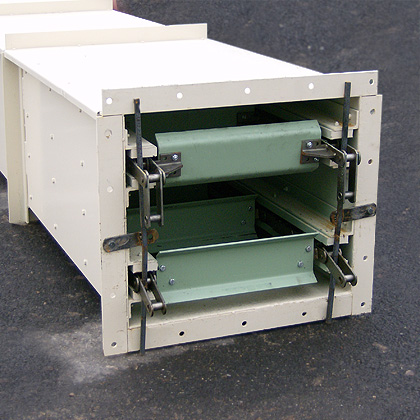

The trough chain conveyors mainly used by us are twostrand chain conveyors with two parallelrunning chains. The drivers out of steel or even plastic are screwed to these chains. Wear is greatly reduced and shavings are largely prevented from getting between chain links thanks to the chain being guided with plastic rails above and below the chain.

The chain conveyors can be fitted with curved sections for upwardgradients of up to 75°, in order to also fill high silos for example. Depending on the wearing characteristics of the material to be coveyed, the trough chain conveyors can also be executed with manganese steel bottom plates welded on the inside. The outputs when conveying sawdust range from 30 to 200 m³/h.